Master in Supply Chain Analytics: Leverage Data to Optimize Your Supply Chain

The Master in Supply Chain Analytics is a specialized program designed to equip professionals with the skills to leverage data and optimize their supply chain operations. With the increasing complexity of global supply chains, companies are seeking individuals who can analyze data and make informed decisions to drive efficiency and profitability. This program combines theoretical foundations with practical applications, enabling students to develop expertise in data analysis, predictive modeling, and supply chain optimization, ultimately enhancing their ability to drive business success. By mastering supply chain analytics, professionals can unlock new opportunities.

Unlocking the Power of Data-Driven Decision Making in Supply Chain Management

The Master in Supply Chain Analytics program is designed to equip professionals with the skills and knowledge needed to leverage data and analytics to optimize their supply chain operations. This program focuses on the application of data analytics and machine learning techniques to improve supply chain efficiency, reduce costs, and enhance overall performance. By leveraging advanced analytics and data visualization tools, professionals can gain insights into their supply chain operations and make informed decisions to drive business growth.

Introduction to Supply Chain Analytics

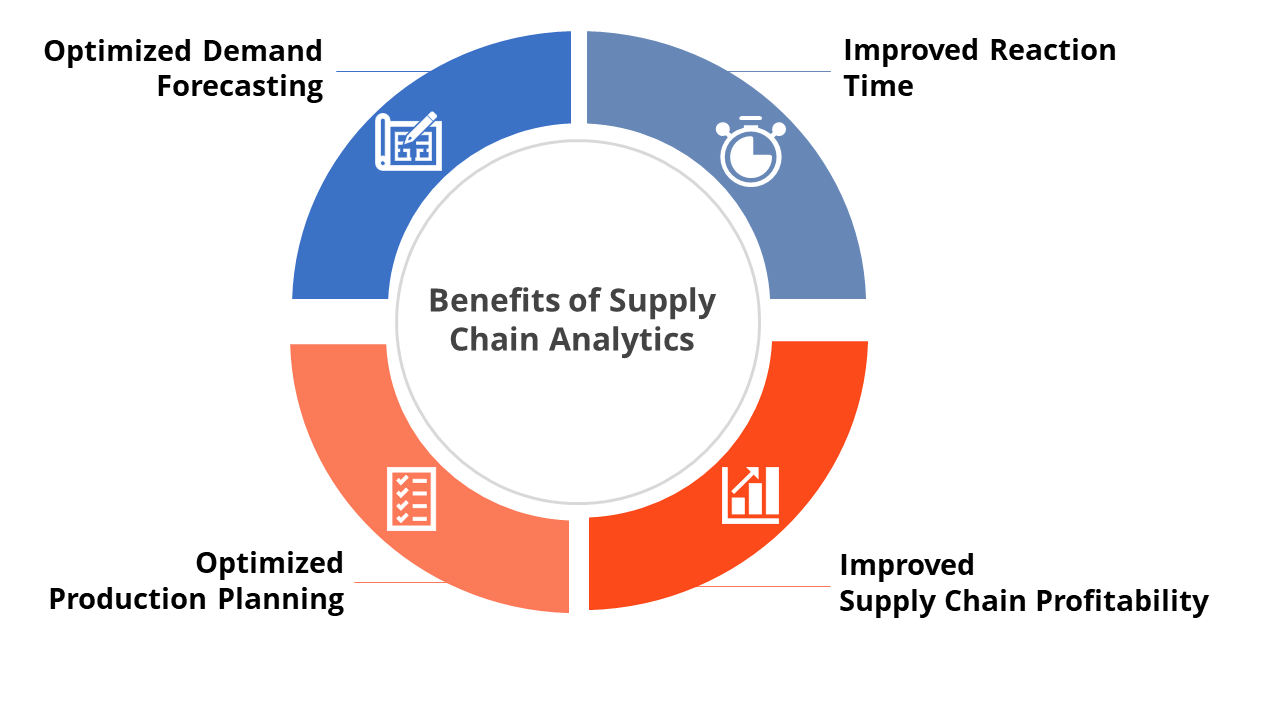

Supply chain analytics involves the use of data analysis and statistical modeling to optimize supply chain operations. This field combines concepts from operations research, industrial engineering, and computer science to develop analytical models and algorithms that can be used to improve supply chain efficiency. The goal of supply chain analytics is to provide insights into supply chain operations and enable data-driven decision making. Key topics in supply chain analytics include demand forecasting, inventory management, and supply chain optimization.

Data-Driven Decision Making in Supply Chain Management

Data-driven decision making is critical in supply chain management, as it enables professionals to make informed decisions based on data analysis and insights. By leveraging data analytics and machine learning techniques, professionals can gain a deeper understanding of their supply chain operations and make decisions that drive business growth. Key applications of data-driven decision making in supply chain management include risk management, supply chain optimization, and demand forecasting.

Tools and Techniques for Supply Chain Analytics

There are several tools and techniques used in supply chain analytics, including data visualization software, statistical modeling software, and machine learning algorithms. These tools enable professionals to analyze large datasets and gain insights into supply chain operations. Key tools and techniques used in supply chain analytics include Tableau, SAS, and Python. The following table highlights some of the key tools and techniques used in supply chain analytics:

| Tool/Technique | Description |

|---|---|

| Tableau | Data visualization software used to create interactive dashboards and stories. |

| SAS | Statistical modeling software used to develop predictive models and analyze large datasets. |

| Python | Machine learning algorithm used to develop predictive models and automate tasks. |

Applications of Supply Chain Analytics

Supply chain analytics has a wide range of applications in various industries, including manufacturing, retail, and healthcare. Key applications of supply chain analytics include demand forecasting, inventory management, and supply chain optimization. By leveraging data analytics and machine learning techniques, professionals can gain insights into supply chain operations and make informed decisions to drive business growth. The use of supply chain analytics can help organizations reduce costs, improve efficiency, and enhance overall performance.

Career Opportunities in Supply Chain Analytics

There are several career opportunities available in supply chain analytics, including supply chain analyst, operations manager, and data scientist. These professionals use data analytics and machine learning techniques to optimize supply chain operations and drive business growth. Key skills required for a career in supply chain analytics include data analysis, statistical modeling, and communication. The demand for professionals with expertise in supply chain analytics is increasing, driven by the need for organizations to optimize their supply chain operations and improve overall performance.

What is the role of data analytics in optimizing supply chain management?

The role of data analytics in optimizing supply chain management is to provide insights and patterns that can help companies make informed decisions to improve their overall supply chain operations. By analyzing large amounts of data, companies can identify areas of inefficiency, optimize their inventory management, and improve their logistics operations. This can lead to cost savings, improved customer satisfaction, and increased competitiveness in the market.

Improving Supply Chain Visibility

Data analytics plays a crucial role in improving supply chain visibility, which is the ability to track and monitor the movement of goods, services, and information throughout the entire supply chain. By analyzing data from various sources, companies can gain a better understanding of their supply chain operations and make informed decisions to improve their supply chain resilience. Some of the key benefits of improved supply chain visibility include:

- Real-time tracking of shipments and inventory levels

- Improved forecasting and demand planning

- Enhanced risk management and mitigation strategies

Optimizing Inventory Management

Data analytics can help companies optimize their inventory management by analyzing data on demand patterns, seasonal fluctuations, and supplier lead times. By using predictive analytics and machine learning algorithms, companies can predict future demand and adjust their inventory levels accordingly. This can help reduce inventory costs, improve fill rates, and increase customer satisfaction. Some of the key benefits of optimized inventory management include:

- Improved inventory turnover and reduced obsolescence

- Enhanced supply chain flexibility and responsiveness

- Increased profit margins and reduced costs

Enhancing Logistics and Transportation Management

Data analytics can also help companies enhance their logistics and transportation management by analyzing data on shipping routes, carrier performance, and warehouse operations. By using geospatial analytics and route optimization algorithms, companies can optimize their shipping routes, reduce transportation costs, and improve delivery times. Some of the key benefits of enhanced logistics and transportation management include:

- Improved on-time delivery and reduced shipping errors

- Enhanced supply chain visibility and tracking

- Increased customer satisfaction and loyalty

What is leverage in supply chain management?

Leverage in supply chain management refers to the ability of a company to use its position and influence to negotiate better deals with suppliers, improve efficiency, and reduce costs. This can be achieved through various means, such as economies of scale, strategic partnerships, and supply chain optimization. By leveraging its supply chain, a company can gain a competitive advantage and improve its overall performance.

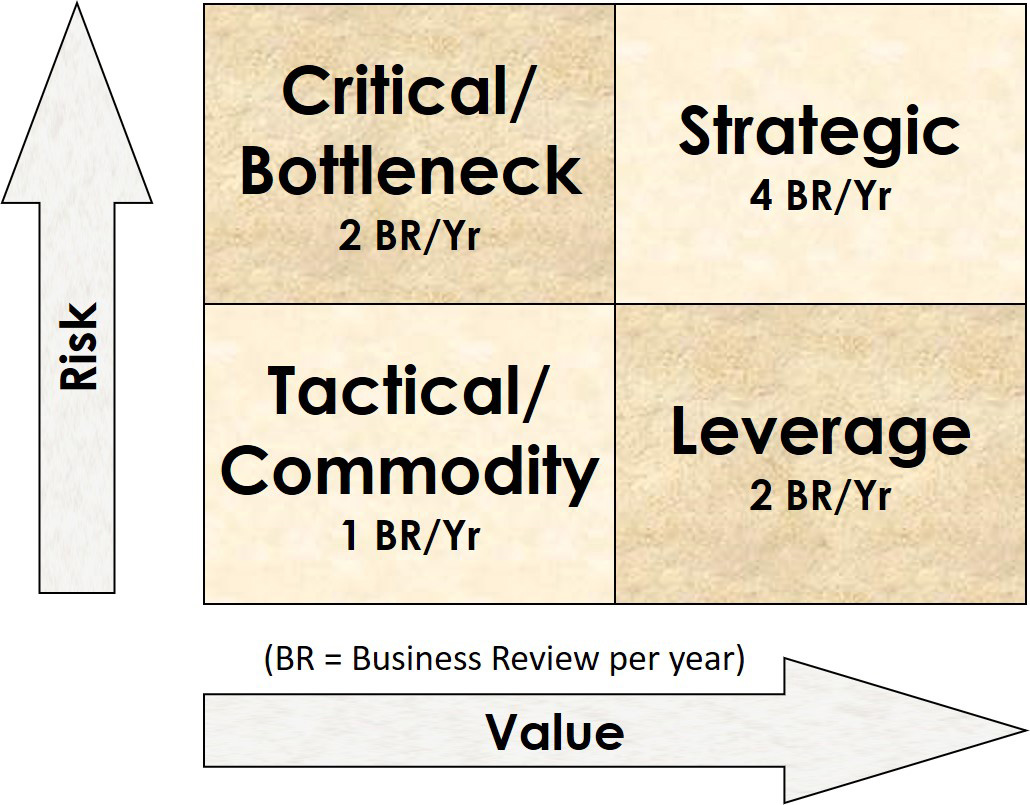

Types of Leverage in Supply Chain Management

There are several types of leverage that can be used in supply chain management, including volume leverage, price leverage, and innovation leverage. These types of leverage can be used to negotiate better prices with suppliers, improve the efficiency of logistics and transportation, and develop new products and services. Some examples of leverage in supply chain management include:

- Using volume purchasing to negotiate lower prices with suppliers

- Implementing just-in-time inventory management to reduce inventory costs and improve cash flow

- Developing strategic partnerships with suppliers to improve communication and collaboration

Benefits of Leverage in Supply Chain Management

The benefits of leverage in supply chain management are numerous and can have a significant impact on a company's bottom line. Some of the benefits include cost savings, improved efficiency, and increased competitiveness. By leveraging its supply chain, a company can reduce its costs and improve its profit margins, making it more competitive in the market. Some examples of the benefits of leverage in supply chain management include:

- Reducing transportation costs through route optimization and mode selection

- Improving inventory management through demand forecasting and inventory optimization

- Increasing supply chain visibility through track and trace and real-time monitoring

Challenges of Leverage in Supply Chain Management

While leverage in supply chain management can have numerous benefits, there are also several challenges that companies must overcome. Some of the challenges include supplier resistance, complexity, and risk management. Companies must be able to negotiate with suppliers, manage complex supply chains, and mitigate risks such as supply chain disruptions and quality control issues. Some examples of the challenges of leverage in supply chain management include:

- Managing supplier relationships and negotiating contracts

- Implementing supply chain technology and integrating systems

- Identifying and mitigating risks and disruptions in the supply chain

Is an MBA in supply chain worth it?

An MBA in supply chain can be a valuable investment for individuals looking to advance their careers in this field. The program provides students with a comprehensive understanding of supply chain management, including logistics, procurement, and distribution. With an MBA in supply chain, graduates can expect to gain a deep understanding of the complex relationships between different components of the supply chain and develop the skills necessary to manage and optimize these systems.

Benefits of an MBA in Supply Chain

The benefits of an MBA in supply chain are numerous, including increased salary potential, improved job prospects, and enhanced career advancement opportunities. Some of the key benefits of this degree include:

- Developing a strong understanding of global supply chain management and its impact on businesses

- Gaining practical experience in supply chain analysis and problem-solving

- Building a network of professional contacts in the field of supply chain management

Key Skills Developed in an MBA in Supply Chain

An MBA in supply chain helps students develop a range of key skills, including analytical skills, communication skills, and problem-solving skills. Some of the key skills developed in this program include:

- Developing strategic thinking and decision-making skills to manage complex supply chain systems

- Gaining expertise in supply chain software and technology to optimize logistics and distribution

- Learning to collaborate and communicate effectively with stakeholders across the supply chain

Career Opportunities with an MBA in Supply Chain

Graduates with an MBA in supply chain can pursue a range of career opportunities, including supply chain manager, logistics manager, and procurement manager. Some of the key career opportunities available to graduates include:

- Pursuing a career in consulting, helping businesses to optimize their supply chain operations

- Working in industry, managing supply chain operations for a manufacturing or retail company

- Starting their own business, providing supply chain services to other companies

What is master data in supply chain?

Master data in supply chain refers to the collection of core data that is essential for the effective management of the supply chain. This data includes information about products, suppliers, customers, and logistics providers, among other things. Master data serves as the foundation for all supply chain operations, enabling companies to make informed decisions, optimize processes, and improve overall efficiency.

Importance of Master Data in Supply Chain Management

The importance of master data in supply chain management cannot be overstated. It provides a single source of truth for all supply chain-related data, enabling companies to maintain consistency and accuracy across different systems and departments. This, in turn, helps to reduce errors and inefficiencies, improve visibility and transparency, and enhance overall collaboration and communication. Some key benefits of master data in supply chain management include:

- Improved data quality and accuracy

- Increased efficiency and productivity

- Enhanced decision-making and analysis capabilities

Key Components of Master Data in Supply Chain

Master data in supply chain encompasses a wide range of critical data elements, including product information, supplier data, customer information, and logistics details. These components are essential for supporting various supply chain processes, such as procurement, inventory management, order fulfillment, and shipping. Some key components of master data in supply chain include:

- Product master data, which includes information about product descriptions, specifications, and prices

- Supplier master data, which includes information about supplier contact details, payment terms, and performance metrics

- Customer master data, which includes information about customer contact details, order history, and shipping preferences

Best Practices for Managing Master Data in Supply Chain

Effective management of master data in supply chain requires a structured approach, which involves establishing clear policies and procedures for data governance, data quality control, and data maintenance. Some best practices for managing master data in supply chain include:

- Implementing a data governance framework to ensure data consistency and accuracy

- Establishing data quality metrics to monitor and measure data quality

- Providing training and support to ensure that users understand the importance of master data and how to manage it effectively

More information

What is the Master in Supply Chain Analytics program and its benefits?

The Master in Supply Chain Analytics program is a specialized graduate degree that focuses on the application of data analytics and statistical methods to optimize supply chain management. This program is designed to equip students with the skills and knowledge required to analyze and interpret complex data sets, identify trends and patterns, and make informed decisions to improve supply chain efficiency and effectiveness. The benefits of this program include the ability to leverage data to drive business decisions, improve forecasting and demand planning, and enhance collaboration with stakeholders across the supply chain. By earning a Master in Supply Chain Analytics, graduates can gain a competitive edge in the job market and pursue leadership roles in supply chain management, operations management, and logistics.

What skills and knowledge are required to succeed in the Master in Supply Chain Analytics program?

To succeed in the Master in Supply Chain Analytics program, students should possess a strong foundation in mathematics and statistics, as well as programming skills in languages such as Python, R, or SQL. Additionally, students should have a basic understanding of supply chain management concepts, including procurement, inventory management, and transportation management. The program also requires strong analytical and problem-solving skills, as well as the ability to communicate complex ideas effectively to both technical and non-technical stakeholders. Furthermore, students should be familiar with data visualization tools such as Tableau or Power BI, and have experience working with large datasets and data mining techniques. By combining these skills with a strong understanding of business acumen and industry trends, students can unlock the full potential of supply chain analytics and drive business success.

How does the Master in Supply Chain Analytics program prepare students for a career in supply chain management?

The Master in Supply Chain Analytics program prepares students for a career in supply chain management by providing a comprehensive education in supply chain analytics, operations management, and business strategy. The program covers a range of topics, including demand forecasting, inventory optimization, supply chain network design, and risk management. Students also gain practical experience through case studies, group projects, and internships, which allow them to apply theoretical concepts to real-world problems. Furthermore, the program emphasizes the development of soft skills such as communication, teamwork, and leadership, which are essential for success in supply chain management. By graduating from the Master in Supply Chain Analytics program, students can pursue a range of career paths, including supply chain manager, operations manager, logistics coordinator, and management consultant.

What are the job prospects and career opportunities for graduates of the Master in Supply Chain Analytics program?

Graduates of the Master in Supply Chain Analytics program have a wide range of job prospects and career opportunities in supply chain management, operations management, and logistics. Some potential career paths include supply chain manager, operations manager, logistics coordinator, management consultant, and data analyst. Graduates can work in a variety of industries, including manufacturing, retail, healthcare, and technology, and can pursue roles in private industry, government, or non-profit organizations. According to industry reports, the demand for supply chain professionals with analytical skills is increasing rapidly, and graduates of the Master in Supply Chain Analytics program are well-positioned to take advantage of this trend. With a strong understanding of supply chain analytics and business strategy, graduates can drive business success and advance their careers in a rapidly changing global economy.

Leave a Reply